OMRON TM kollaborative robotter

Bestil en cobot-demo med en ekspert

Mød vores fleksible medarbejdere

Opdag den fleksible robotløsning

OMRON TM-robotter er rettet mod producenter, der har fokus på fremtiden og vil sætte skub i produktionen. Cobots er ideelle kolleger, der automatiserer ensformige og gentagne opgaver som f.eks. maskinpasning, læsning og aflæsning eller montageopgaver.

Vores kollaborative robotter er sikre, enkle at programmere og nemme at integrere med andet udstyr, hvilket er et stort skridt i retning af at skabe et intelligent produktionsmiljø, hvor mennesker og maskiner arbejder sammen i harmoni.

Mød dine nye kolleger

- Rækkevidde

- Nyttelast

- Maks. hastighed

TM 5 - 700

- Rækkevidde 700 mm

- Nyttelast 6 kg

- Maks. hastighed 1,1 m/s

TM 5 - 900

- Rækkevidde 900 mm

- Nyttelast 4 kg

- Maks. hastighed 1,4 m/s

TM 12

- Rækkevidde 1300 mm

- Nyttelast 12 kg

- Maks. hastighed 1,3 m/s

TM 14

- Rækkevidde 1100 mm

- Nyttelast 14 kg

- Maks. hastighed 1,1 m/s

Nem at implementere

Indbygget vision

Forenklet programmering

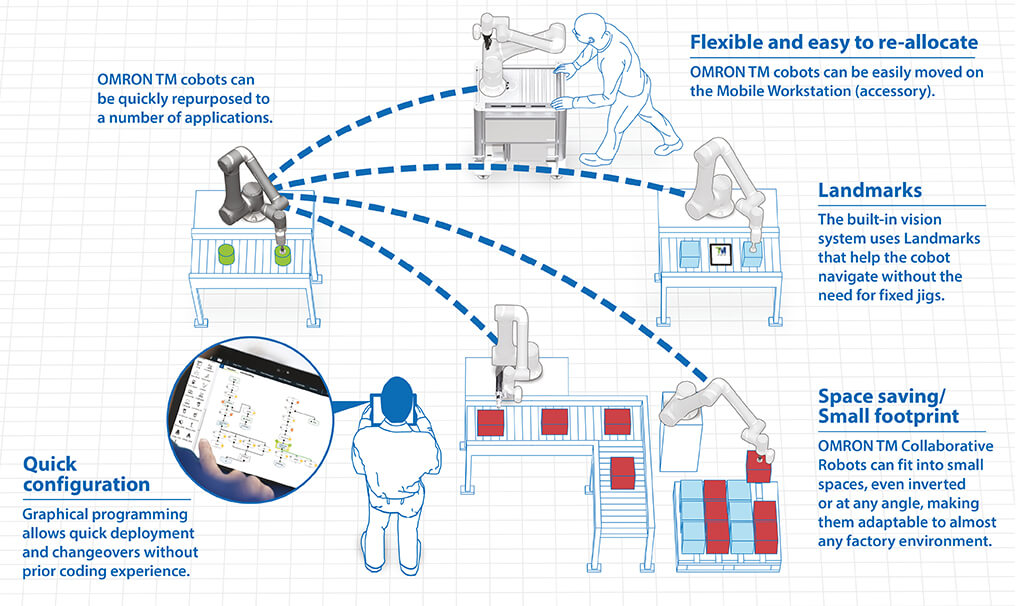

Vores grafiske programmering gør det muligt for brugerne at automatisere en opgave med intuitiv flowbaseret software, så en cobot kan sættes i arbejde direkte out-of-the-box, uden kodning.

Suppler din applikation

OMRON har indgået et samarbejde med en række virksomheder om at tilbyde en lang række eksterne enheder, der hurtigt og nemt kan integreres med vores cobots, hvilket giver mulighed for hurtigere implementering og investeringsafkast. De kaldes tilsammen Plug & Play-enheder og -software, og de er designet til at kunne betjene en lang række kundeanvendelser og opfylde OMRONs højeste teststandarder.

Applikationer

Uanset om du arbejder inden for automobil-, fødevareindustrien, emballage, plast, metal eller farmaceutisk produktion, er OMRON TM kollaborativ robot designet til at tilpasse sig næsten enhver industri.

-

Cobots give gear manufacturer Fischer Gears a competitive production edge

Danish gear manufacturer, Fischer Gears, has boosted the competitiveness of its production process - especially on larger series – by installing two Omron TM robots. The collaborative robots (cobots) free experienced employees to focus on more value-adding tasks.

02:31

Maskinpasning

-

Meet the RB1200 Cobot Palletiser

OMRON and Reeco Automation have partnered to bring you the RB1200 palletiser. A safe, flexible and versatile solution to the EOL palletising process, designed to improve production efficiency, provide enhanced flexibility and save costs. Read more:

02:18

Palletering

-

Precise and consistent assembly of magnets and coatings with a cobot for the automotive market

LITMAT, a company with over 70 years of experience in supplying components for the automotive industry, has recently introduced the OMRON TM5 cobot within its magnet assembly plant on metal oil drain plugs. The goal of the solution is to simplify the process of assembling the magnets that are necessary to attract any impurities in oil. The cobot takes care of the complete process, from applying the glue, inserting the magnets in the plugs and the verification of the amount of glue applied with the integrated camera. All data is managed centrally by an OMRON NX102 PLC, which can be connected to the MES for integrated supervision of the entire production cycle in real time. At the terminal (OMRON NB Series 7'') the operator can see the information related to processed pieces, types, rejected pieces, causes of stoppage as well as timing, and modify all the parameters relating to the formats if necessary, such as height of the cap, magnet and magnetization. All these variables are supplied to the cobot, which then proceeds with the machining according to the quotas assigned for each different piece to be assembled, without expensive tooling operations. Like all OMRON cobots, even the OMRON TM5 installed in LITMAT can operate in the presence of personnel. Two barriers equipped with a safety module are connected to the PLC and allow the OMRON TM5 to enter collaborative mode. In this way, the employees in charge of sorting the magnets in boxes can work without any risk close to the automated area. Overall, the solution enables LITMAT to assemble approximately 180 caps per hour for a total of 1500 pieces in each 8-hour shift. All with unparalleled consistency: the cobot always exerts the same pressure on the plug, ensuring repeatability and consistent quality. About LITMAT S.p.A. LITMAT S.p.A. is specialized in the manufacturing of metal threaded plugs that are supplied mainly to the automotive industry (oil drain plugs) and to manufacturers of hydraulic, pneumatic, hydronic and mechanical equipment. They are the largest Italian manufacturer in this field, making a full line of plugs, in different materials (steel, brass, aluminium), according to various national standards (DIN, SAE, UNI, etc…), with any thread (metric, english or other), cylindrical and taper. LITMAT also manufactures many different types of magnetic plugs and we can make almost any plug according to the client’s specifications or drawing. LITMAT S.p.A. is particularly competitive in the international market in the production of cold formed steel plugs according to DIN 906, 908, 909 and 910 and special plugs according to customers’ drawings. Since 1950 LITMAT S.p.A. has been O.E. supplier of the most important automobile and truck manufacturers in Italy for all drain and fill plugs in the oil pan, gear box and differential. Many of the most important manufacturers of mechanical components (axles, gear boxes, pumps, etc…) for the automotive and industrial vehicle sectors and many important fastener dealers in Europe are in the list of their clients. About OMRON Electronics S.p.A. OMRON Corporation is one of the world leaders in automation and its work is based on the core technology "Sensing & Control + Think". Established in 1933, OMRON has approximately 30,000 employees worldwide and offers products and services in approximately 120 countries and regions. OMRON operates in various sectors, including industrial automation, electronic components, systems for social infrastructures and solutions for healthcare and the environment. In the industrial automation sector, OMRON supports innovation in the manufacturing sector by proposing advanced automation products and technologies, as well as through widespread customer assistance, with the aim of contributing to the improvement of society. A complete range of machine automation, 200,000 input, logic, output, robot and safety devices make OMRON one of the 2,000 largest companies in the world according to Forbes, listed on NASDAQ and a top spot in the Dow Jones Sustainability Index and for the fifth consecutive time among the "Top 100 Global Innovators" of the world selected by Clarivate Analytics. Integrated Automation: Achieve seamless integration of technology through advanced control Intelligent Automation: Transforming factory data into valuable information Interactive Automation: Create a harmonious interaction between humans and machines

01:15

Montering

-

Traceability 4.0 with the OMRON TM cobot

This demonstration at the Gruppo Romani plant shows how a cobot to carry out intelligent labeling on any product format. The application, created by Bluengineering, a company specialized in process control in the ceramic industry, uses the OMRON TM5 Cobot with an outreach of 700 mm, taught in a few minutes by manually defining the gripping, passage and deposit points. The objective: application of labels on one of the four front sides of the outgoing package, quickly managing format changes quickly, without complex tooling operations. The cobot carries out most of the repetitive operations, while workerscan now focus on activities with greater added value. The collaborative nature allows the cobot to work safely in the presence of personnel. Specifically, this is made possible thanks to the integrated monitoring features that dynamically constrain the force and pressure to be exerted in the vicinity of the operator. The cobot can be programmed to stop or evaluate all possible interactions in which to limit its action so that accidental contact with humans does not become dangerous. The integrated vision system on the robot allows reading of the codes (bar code or QR), the control of the correct positioning, as well as the tracking and verification of the packages. All data is sent and managed centrally by an OMRON NX102 PLC connected to the MES for integrated supervision of the entire production cycle in real time. At the terminal, the operator can see the status of production, the batches in transit, the number, speed and method of labels to be printed and applied. Thanks to the cobot, companies can take advantage of a more versatile, more continuous and more efficient solution for labeling operations. Especially when beyond speed, they have to deal with the various different product formats: the reduction of downtime due to format change can reach up to 70% compared to a traditional mechanical axis system. All in maximum safety. Bluengineering s.r.l. Bluengineering srl is an engineering company operating in process control in various production sectors: ceramic, packaging, food, chemical and mechanical, with particular attention to automation dedicated to the production of porcelain stoneware ceramic tiles. The company is strongly oriented towards technological innovation, and strives for the continuous improvement of production processes, using the most modern equipment available on the world market. Bluengineering also stands out for its fast, efficient and precise after-sales service. Among the most important activities developed by Bluengineering Tecnologie: Upgrade and regeneration of obsolete automatic systems Programming of PLCs and industrial PCs - Electrical systems for industrial automation - Electrical panels for industrial automation and process control - Dry coloring of atomised products - Systems for coloring the slips - Weighing belts for atomised powders, granulated products and raw materials. Romani Group S.p.A. Ceramic Industries The Romani Group, founded in 1968, is an expression of the most authentic Made in Italy entrepreneurship. Born in the name of passion, competence and technological research, today it is recognized and appreciated all over the world for the unique style of the ceramic solutions proposed and fully represents the dedication to product quality with a view to continuous evolution. The Romani Group, through its Serenissima, CIR Ceramiche, Cercom and Cerasarda brands, tells an industrial story with a high craftsmanship value, integrated with technical and production innovation projected into the future. The ability to interpret and anticipate the aesthetic trends of the market, supported by cutting-edge plant design, is the basis of the extraordinary offer of the Romani Group. The quality of the product and services, customer satisfaction, respect for the environment and the territory are mandatory commitments for the Romani Group, fundamental cornerstones of the business philosophy supported by the Romani family and pursued daily by every single component of the company. Omron Electronics S.p.A. OMRON Corporation is one of the world leaders in automation and its work is based on the core technology "Sensing & Control + Think". Established in 1933, OMRON has approximately 30,000 employees worldwide and offers products and services in approximately 120 countries and regions. OMRON operates in various sectors, including industrial automation, electronic components, systems for social infrastructures and solutions for healthcare and the environment. In the industrial automation sector, OMRON supports innovation in the manufacturing sector by proposing advanced automation products and technologies, as well as through widespread customer assistance, with the aim of contributing to the improvement of society.

01:23

Emballage

Designet til fleksibel produktion

Livscyklus for produkter bliver hele tiden kortere. Automatiseringsløsninger kan understøtte dine behov for at tilpasse produktionsprocesserne hurtigt.

Skab din applikation inden for en time

Integreret vision

Landmark-navigation

Under produktion af højt mix af små mængder med hurtig udskiftning kan kunderne genimplementere robotten uden at bruge tid på at rekalibrere visionsystemet. Vores cobotter bruger landmarks til nem omplacering uden behov for jigs eller rekalibrering.

Et landmark er et fysisk objekt, der kan genkendes af robottens indbyggede kamera, og det fungerer som en afmærkning, der hjælper robotten med at navigere.

Valg af cobot vs. industriel robot

OMRON TM kollaborative robotter ændrer den måde, den traditionelle fabrik plejede at fungere på. Der er ikke længere brug for fysiske sikkerhedshegn. OMRON TM-cobots er designet til produktion af højt mix af små mængder med en hastighed, der kan sammenlignes med menneskelige medarbejdere, og de kan arbejde sammen med mennesker i harmoni.

Traditionel industriel robot

Traditionelle industrielle robotter skal adskilles fra menneskelig aktivitet ved hjælp af et sikkerhedshegn og skal fastgøres på ét sted, da de normalt anvendes til en bestemt opgave.

- Kompleks konfiguration

- Roboteksperter er påkrævet

- Faste løsninger

- Stort footprint

- Beskyttelseshegn er påkrævet

- Høje ekstraomkostninger

Kollaborativ robot

Cobots blev skabt til at arbejde sikkert og i harmoni med mennesker. De kan flyttes fra en placering til en anden for at arbejde på forskellige opgaver.

- Hurtig konfiguration

- Der kræves ingen eksperter

- Fleksibel og nem at reallokere til nye opgaver

- Pladsbesparende/lille footprint

- Mulighed for samarbejde mellem menneske og maskine

- Investeringsafkast inden for kort tid