The Dutch fish manufacturer achieves 75% reduction in manual labour and up to five times the speed with the automated production line. The solution created by Innovotech BV, a local automation partner, includes control and vision systems from OMRON, and enables the company to preserve competitive production in the Netherlands.

Raw brined herring is an acquired taste and holds a special place in many Dutch people’s hearts. Combined with a sprinkling of raw onions, many say that taking a big bite of the herring vertically, holding onto the tail of the fish is the only right way to eat it. However, this poses special requirements during the filleting process, as the tail of the fish needs to be preserved, in addition to demanding quality requirements.

Seafood Parlevliet has produced packaged fish products since 1968 at their family-owned factory at the harbour of Ijmuiden, in the Netherlands. Specializing in fish delicacies such as herring, mackerel and fried fish to the European market, they are a market leader in the retail sector and also supply to the wholesale trade and the healthcare and catering markets.

The Challenge

Filleting herring usually involves several manual steps, and for example skinning the fish could only be done by skilled and experienced workers. In Northern Europe, it is especially difficult to find the right people for the job. In addition, the seafood market in the Netherlands is very competitive.

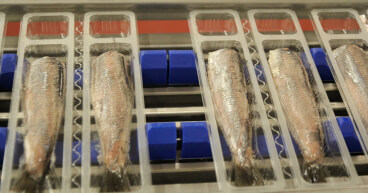

To ensure efficient and competitive herring production for Seafood Parlevliet, Innovotech BV, a local automation partner, started developing a new prototype to automate the manual steps in the process, such as skinning and scraping the fish. In addition, the fish needed to be cut to the right size, while keeping the tail. High quality, safety and hygiene needed to be ensured throughout the entire process.

The Solution

The automated production line includes various OMRON components, such as frequency regulators, servo drives, feeding solutions, safety blocks as well as the brain of the machine in the panel solution. The panel building for the electrical control of the system was carried out by A. Hagoort Besturings techniek, a specialist in machine control solutions.

In addition, OMRON FH vision system and cameras, paired with lighting and bespoke machine vision software, were implemented to carry out several vision checks during the process. The inspection ensures that the appearance of the fillets meets the high quality standards of the company, so that for example no traces of blood are present, and that the skin and fins of the fish consistently meet the customer requirements. Any fish that does not meet the requirements will be removed from the production line.

The Benefits

“We believe that finding the perfect technical solution using the best components available has resulted in the perfect solution also in terms of quality and economics,” said Rick van den Berg, R&D Manager at Innovotech BV. “Thanks to continuous development, the high-quality components from a single source, and the vision expertise of OMRON, we have been able to automate the filleting and packaging operation. The machine can now handle any type of herring with high precision and accuracy, while ensuring consistency for the customers,” Van den Berg concludes.

Contact us for more information