Robotics Integrated Controller

For applications requiring high-speed processing for machine control, safety, reliability and maintainability.

Our Robotics Integrated Controller perfectly synchronizes automation technology so that customers can improve the speed and accuracy of their production, simulate entire production line, simplify maintenance, and reduce time-to-market.

- Up to 8 robots control per CPU

- Integration of Robotics, Logic, and Motion in one CPU

- Conforms to IEC 61131-3 (JIS B 3503) standard programming and PLCopen function blocks for motion control

- Conforms to IEC 61131-3 (JIS B 3503) standard programming and traditional V+ scripting for robot and motion control

- Programming with variables allows users to create complex programs efficiently

- Models with SQL DB Functionality

- Offers speed without compromising on reliability and robustness expected from PLCs.

- Linear and circular interpolation.

- Electronic gear and cam synchronization.

- Fast and accurate control by synchronizing all EtherCAT devices, such as vision, servos, robots, and IO with the controller.

- Offers speed without compromising on reliability.

Specifications & ordering info

| Produkt | Supports DB connection | Max. number of robots | Max. number of synchronous axes | Primary task cycle time | Program memory | Variables memory | Communication port(s) | Max. number of remote I/O nodes | Supports sequence control | Supports motion control | Supports robotics control | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

No | 8 | 16 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 16 servo axes |

|

|

|

Yes | 8 | 16 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 16 servo axes, SQL client |

|

|

|

No | 8 | 32 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 32 servo axes |

|

|

|

Yes | 8 | 32 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 32 servo axes, SQL client |

|

|

|

No | 8 | 64 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 64 servo axes |

|

|

|

Yes | 8 | 64 | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | Robotic Integrated Controller NJ5: 8 robots and 64 servo axes, SQL client |

|

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Kontakt mig Robotics Integrated Controller

Tak for indsendelsen af din forespørgsel. Vi vil vende tilbage med svar så hurtigt som muligt.

Vi har desværre tekniske problemer. Din formular er ikke modtaget. Vi undskylder og beder dig om at prøve igen senere. Detaljer: [details]

DownloadTilbud på Robotics Integrated Controller

Med denne formular kan du bestille et tilbud på et eller flere af vores produkter. Venligst udfyld alle de felter der er markeret med *. Dine personlige oplysninger vil blive håndteret fortroligt.

Tak for din forespørgsel. Vi vender tilbage med de ønskede oplysninger så hurtigt som muligt.

Vi har desværre tekniske problemer. Din formular er ikke modtaget. Vi undskylder og beder dig om at prøve igen senere. Detaljer: [details]

DownloadFeatures

The Robotics Integrated Platform is the next revolutionary step in the SYSMAC ecosystem that seamlessly integrate the full ORT Fixed Robotics product line.

Total Integration (Control): Unified control automation + robotics

Process Integration (Faster Time-to-market): Applications can be developed from design through commissioning, operation, and continuous improvement

Supply Chain Integration (Flexibility): Users can easily reprogram (PLC and robots), modify, or scale production, providing flexibility to adapt to fluctuating demands The NJ-R machine controller with new Robot Integrated CPU supports up to 8 robots as well as independent motion axis control.

6 CPU’s:

- NJ501-R300: 8 robots + 16 motion axis

- NJ501-R400: 8 robots + 32 motion axis

- NJ501-R500: 8 robots + 64 motion axis

- NJ501-R320: 8 robots + 16 motion axis + SQL Functionality

- NJ501-R420: 8 robots + 32 motion axis + SQL Functionality

- NJ501-R520: 8 robots + 64 motion axis + SQL Functionality

Benefits for the customer

- Faster evaluation (System Integrator & OEM)

- Early ROI calculation and design validations thanks to simulation software

- Changeover improvements of future products can be validated by simulation.

- Investment cost can be calculated in advance.

- Cycle time estimation

- Improve Conception & Planification

Lower commissioning time (System Integrator & OEM)

- Reduce integration time with programming off-line.

- Xpert modules reduces integration time and learning curve.

- Reduce mechanical and electrical design burden by emulating full cells through the Sysmac Platform.

Lower cost of ownership

- Real time synchronization between robot and PLC (motion control and rest of ECAT devices) improve productivity.

- Recipe manager makes modifications easy and minimize the product change over time.

Technology

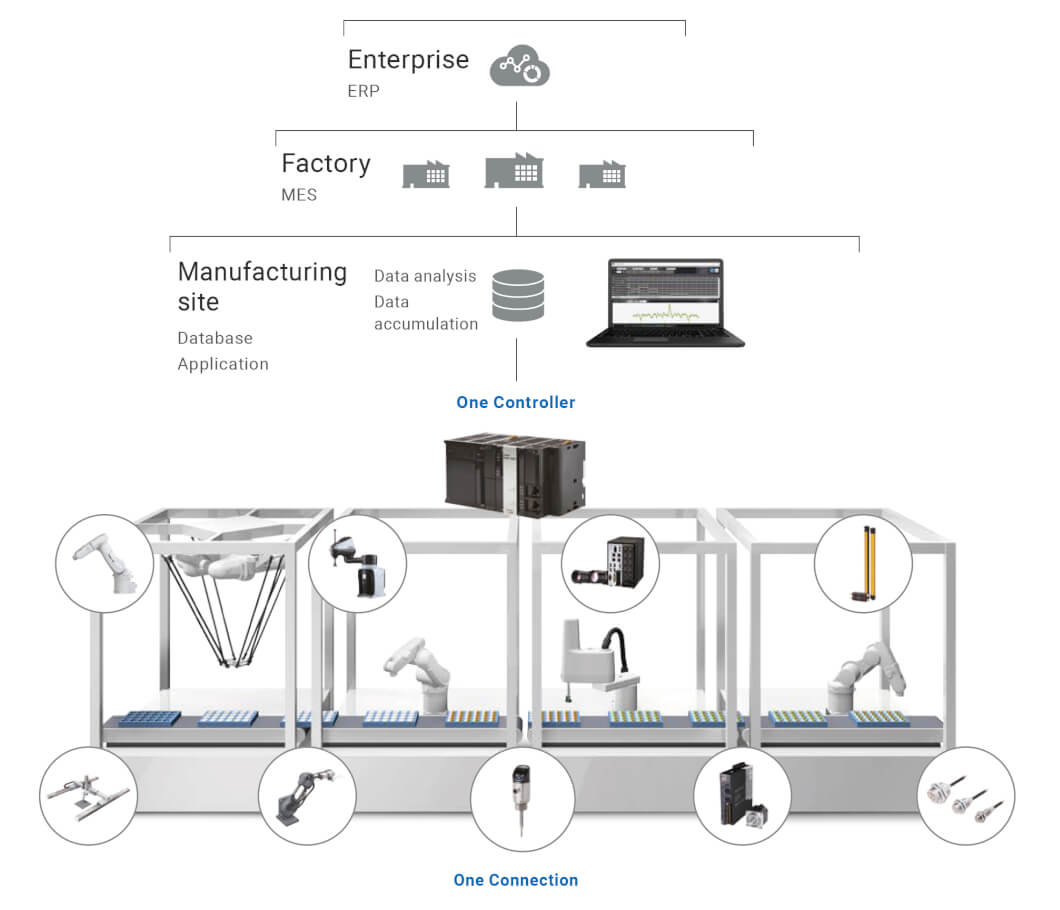

One Controller approach: Seamless, smooth integration of sequence, motion, and robot control

Our One Controller approach integrates robot control, in addition to sequence and motion control, to a single controller. This enables synchronized control of robots as well as other devices. It also enables users to collect information on devices that is aligned to a common timeline and therefore of practical use.

Integration from the

- Enterprise – ERP

- Factory - MES

- Manufacturing site – Database application and analysis

- Production line through integration of different products

Relaterede produkter

-

Boost Your Productivity

-

Articulated robot for machining, assembly, and material handling

-

SCARA robot for precision machining, assembly, and material handling

-

Gain more out of production with a higher payload and faster cycle time

-

Parallel robot ideal for use in the food and beverage, pharmaceutical, and healthcare industries

-

Four-axis parallel robot achieves high speed and high precision

Downloads

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)