Smart Manufacturing

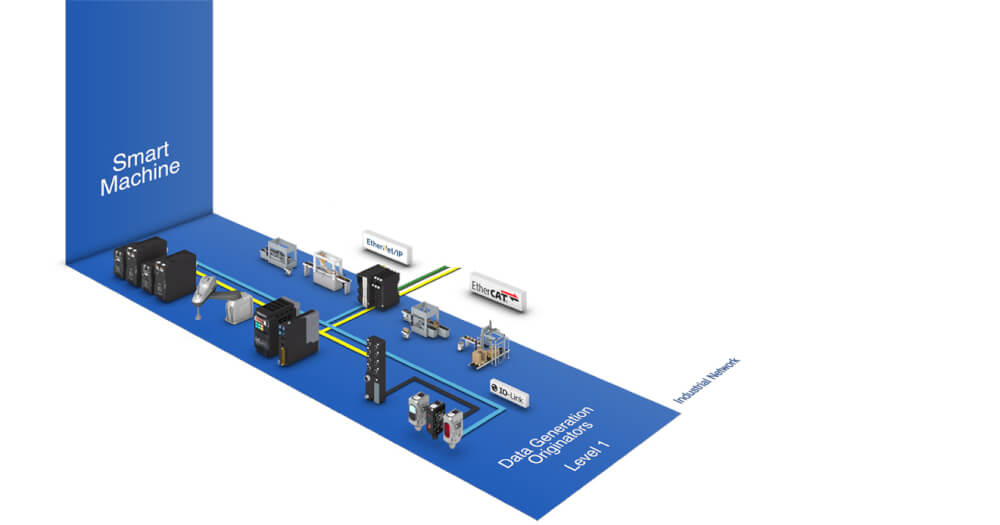

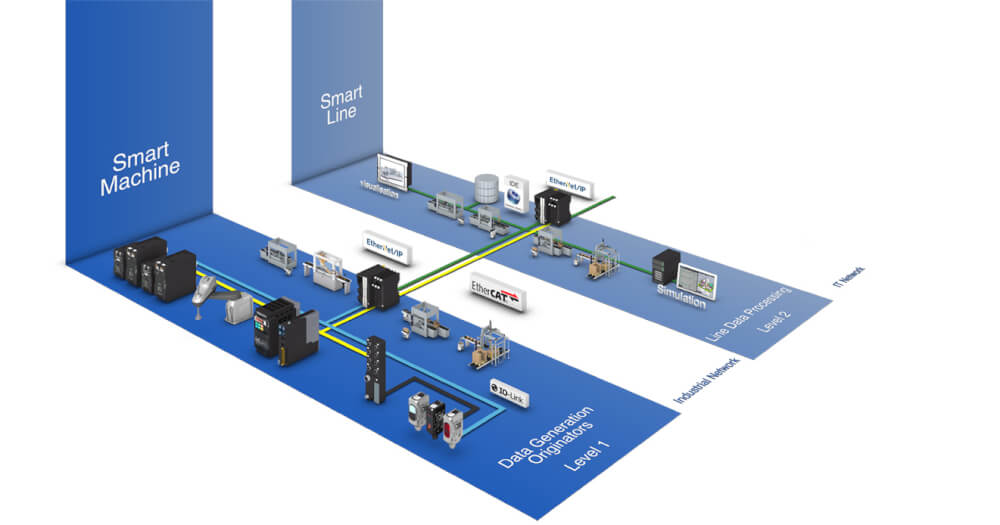

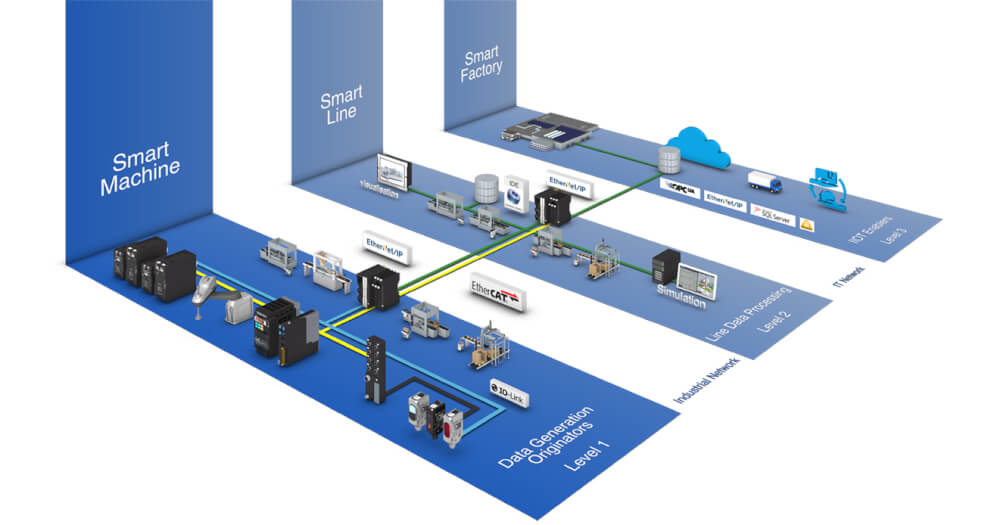

To bring this vision to life, we offer smart manufacturing solutions on three levels: Smart Machine, Smart Line and Smart Factory. In these levels, each device plays a unique role, and together they create a solution that’s greater than the sum of its parts.

Smart automation

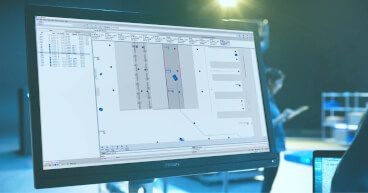

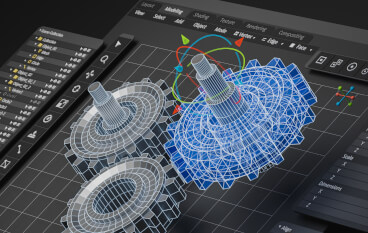

Smart motion control, powered by OMRON’s PLC and motion simulation tools, enables agile and precise production. By simulating and adjusting in real-time, you can streamline setup and reduce errors.

Smart sensors

Smart sensors and components are the backbone of a smart factory, enabling real-time data exchange for predictive maintenance and improved efficiency.

Smart Maintenance

Smart maintenance provides self-explanatory maintenance information in the machinery at sensor level, notification module and remote connectivity.

Smart integration from controller to software with Sysmac Platform

Sysmac is OMRON's all-in-one automation platform, uniting control, motion, safety, vision, and networking with seamless integration and efficiency.

Rewind and resolve unexpected issues with Automation Playback

Resolve unexpected machine failures with the NX5 Controller, featuring the innovative Automation Playback function and keep operations running smoothly.

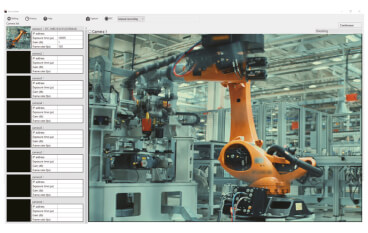

24/7 machine monitoring with Vision Factory Recorder

A 24/7 machine monitoring solution, the Factory Drive Recorder software and hardware package records live video before the defect occurs so that process engineers can review and rectify the error.

Optimized workflow and AMR fleet management

Centralize control, optimize workflows, manage tasks, and scale securely for your manufacturing needs.

Turn data into meaningful information with i-BELT Data Services

Link production and management challenges with manufacturing data to solve your production challenges. OMRON is your co-creation partner for continuous improvement.

IT/OT convergence in industrial automation

Bridging the gap between OT and IT is vital to turning today’s factory visions into the reality of tomorrow’s smart, connected manufacturing.

Smart manufacturing ensures:

-

Quality assurance

Implement automated quality checks to maintain high standards, reduce defects and enhance product consistency.

-

Flexible and adaptive design

Enable manufacturing systems to adjust automatically, adapt to product variations and minimize downtime for design changes.

-

Accelerated time to market

Reduce production cycles and respond quickly to customer demands.

-

Stock prediction

Leverage real-time data to predict inventory needs accurately, reduce waste and ensure optimal stock levels.

-

Continuous improvement

Drive operational excellence in manufacturing processes through data-driven insights and proactive problem-solving.

Smart manufacturing technology

Customer References, Examples and Related Articles

Taking the first steps to successful digitalisation

12. november 2024 Building a digital factory isn’t an end or a reason in itself. A digital factory is a tool that gives manufacturing businesses the flexibility to respond to changes in the market - whether that is innovation trends or cost increases, and whether they are operating in the food & beverage, personal care, pharmaceutical or automotive sector.

Digitising with open standards: the recipe for a good night’s sleep

2. september 2024 In a manufacturing context, the purpose of digitisation is to help factory managers sleep soundly at night.

Real time data monitoring ensures defect-free relays

OMRON Automotive Electronics Italy has upgraded its production line of Power and G8HN relays for the automotive market.