Moving to smarter Maintenance

Maintenance is a vital to assuring 24/7 operations. Even the failure of a single component can have a massive impact on operations, while energy and maintenance expenses are a major part of the lifecycle costs of automatic machines

Keeping production lines and systems running optimally often relies on a skilled maintenance team. Plant managers need a solution to minimize maintenance cost. Are you considering moving from traditional to smarter maintenance?

With smarter maintenance solutions you can:

- Assure short downtime for maintenance

- Receive a preventive notification to plan maintenance tasks based on actual needs

- Become less dependent on staff availability and mobility, and lower commissioning and maintenance costs

- No worries about access constraints and safe conditions for the operator

Take the 4 steps towards smarter maintenance with OMRON:

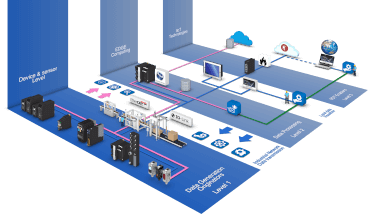

OMRON’s view consist to GENERATE and USE maintenance information with No NEED of extra layer of complex elaboration in Cloud. It provides, in the machinery, self-explanatory Maintenance information at sensor level, notification module and remote connectivity.

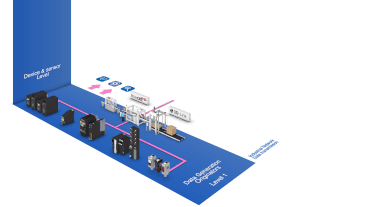

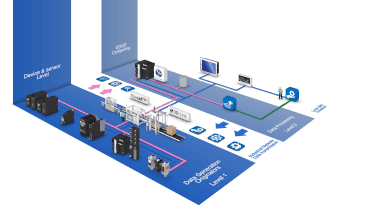

All those elements are merged in a three-levels solution in which each device singularly has his own part in this story and the solution is more than the sum of each singularity.

LEVEL 1: Generate self-explanatory Maintenance information

OMRON components, sensors and actuators are designed to provide Realtime system health information.

LEVEL 2: Elaborate Maintenance Data and information at the edge

Elaboration is done at machine level for quick reaction time and alerts.

LEVEL 3: IoT enabler and Secure remote access

Reduced Spend on Site Maintenance Visits and cost optimisation.