Today's challenge: Inspection complexity

Our Solution: Advanced Inspection Systems at High Speed

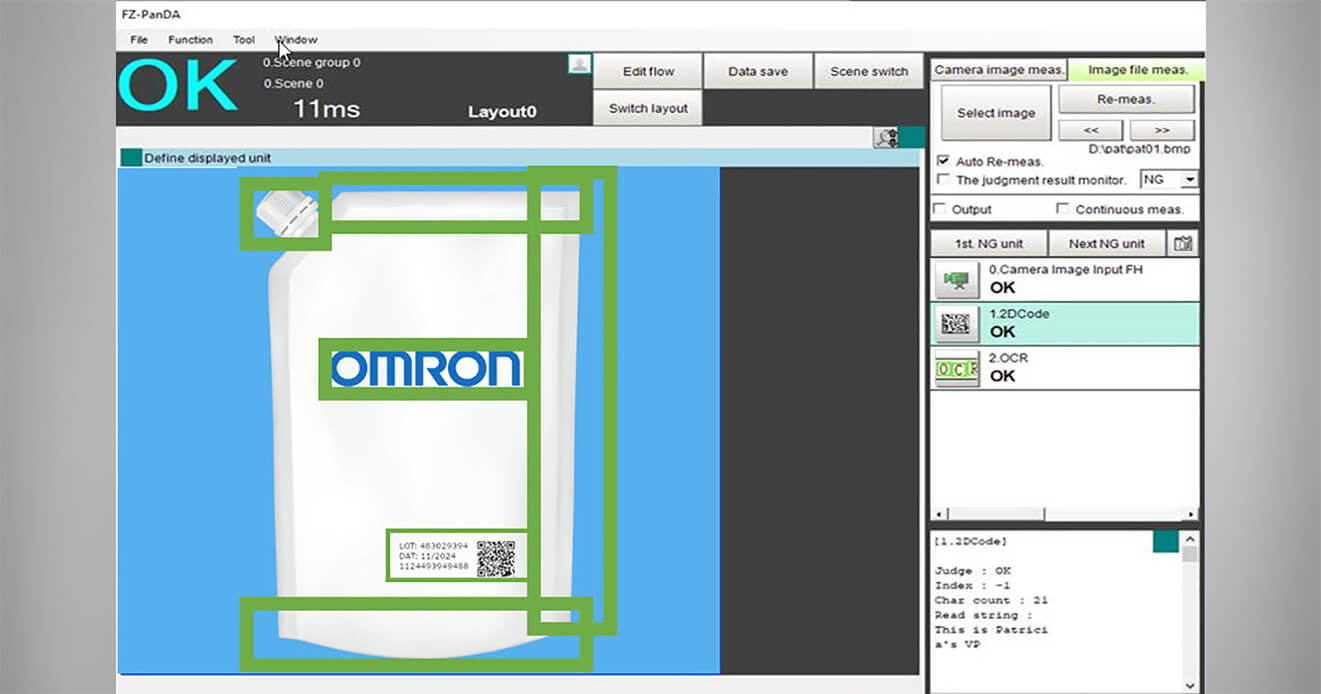

Additionally, we provide parallel processing for different inspections. This results in efficient and reliable detection of different defects at high speed. Our advanced algorithms recognize difficult-to-read characters in variable light conditions and on difficult surfaces.

Benefits of our Packaging & Label Integrity solutions:

-

Reliable inspection in complex environments

-

Advanced performance at high speeds

-

Increased flexibility with changing variables and materials

-

Easier integration and scalability with robotic systems

See Our Solution in Action

-

Flexible quality inspection solution with machine vision at Novio Packaging

Since 1978, Novio Packaging A/S has produced and distributed primary packaging and packaging solutions for various markets including pharmaceuticals, cosmetics and food and beverage industries. It is vital that the bottles that they produce for example for juice manufacturers are free from any defects or items that could contaminate the contents or affect the appearance of the bottle. The Novio factory in Denmark needed a sophisticated and flexible quality inspection system to cope with changes in the types of bottles being produced, and to achieve the right levels of quality. Novio opted for a versatile solution from OMRON including the FH vision system as well as FQ2 cameras. The system detects any defects, such as scratches or dust, that could affect the quality of a bottle. Any bottle identified as having defects is automatically discarded.

02:51