Automation blog

Digitalization in the automotive industry: Seven tips for smart production

2. november 2022 If you want to grow and master crises, you have to be digitally fit – this also applies to the important automotive sector. There is no way around digital tools for addressing customers or productivity. Artificial intelligence (AI) and sustainability are key drivers and focus topics, as a study by Capgemini shows. Experts from Gartner point out the importance of open-source collaboration approaches, holistic ecosystems, and technology partnerships. But what should we look out for in digitalization and intralogistics in the production of the future? We want to answer this question in two parts. We start with tips on digitization in the smart factory. As an automation expert, OMRON has been accompanying manufacturers and suppliers on their way to more digitalization sophistication for many years.

How can adaptive AI inspection contribute to flexible manufacturing?

4. oktober 2022 Consumers today demand customized products to meet their personal needs and tastes. Instead of producing items that are ‘made to shelve’ and ‘sent to stock’, manufacturers must personalize products that are ‘made for me’ and ‘sent to me’. This is revolutionizing production and forcing companies to rethink their processes. At the same time, ensuring zero complaints and zero defects is a must.The trained eye of an experienced vision inspector is quick to spot errors, but a routine task like this is tiring, and cannot be carried out at each step of the production, especially due to the current labor shortages in many industries. But could this task be automated also in high-mix low-volume production? Could a smart vision system or an ‘electronic eye’ replicate the discernment of the human eye, with the added benefit of repeatability and robustness? The latest AI-enabled adaptive inspection can overcome the challenges of automated quality inspection, with improved flexibility, productivity, and adaptability.

Artificial Intelligence: hope, hype and FOMO

22. september 2022 Ten years ago when we received enquiries about AI-based projects, they were mainly driven by hype or FOMO. When I asked why they wanted to get into AI, the answer, more often than not, was either ‘because my boss asked me to’, ‘because we have a lot of data’ or ‘because it seems like an interesting area’. None of these were particularly solid reasons and certainly didn’t justify the hefty investment that AI applications would have required at that time.That is changing, and hope, rather than hype or ‘FOMO’, is the driver. Customers don’t ask whether we can help them with AI anymore. They ask us whether we can help with predictive maintenance, quality control or process optimisation. They come to us with a problem that they want us to help solve. The adoption of AI is no longer a motive or an aim in itself. Instead, AI has become an ‘enabler’.Whatever the industry - whether food & drink, pharmaceutical, electronics or automotive - the end goal is the same: producing high quality, defect-free products at a lower cost, using less energy and less labour. And AI can be one of a suite of solutions for achieving those objectives.

Automation adapts to sustainable packaging

16. august 2022 Have you ever ordered a small item online, and then felt incensed when it arrived in an oversized box packed out with bubble wrap, air-filled cushions or paper inserts?

Flexible Manufacturing Roadshow: Taking the factory of the future across Europe

16. juni 2022 What if you could see, feel and touch the factory of the future? What does it take to realize flexible, efficient, and sustainable production? This is the idea behind OMRON’s unique Flexible Manufacturing Roadshow travelling across Europe this year. The roadshow features exclusive demonstrations of human-machine collaborative solutions not usually seen outside of a factory setting due to their size and scale.

Building the Factory of the Future together

16. juni 2022 As one of the largest business units at OMRON, we aim to further develop the Den Bosch plant to serve the needs in the EMEA region.

Traceability in Automotive: What decision-makers and experts should look out for now

23. maj 2022 From e-mobility to autonomous driving, from skills shortages to digitalization: The automotive industry is undergoing a profound change, marked, for example, by a shift to globalized platforms and standardized vehicle architectures. On the one hand, production is becoming increasingly efficient, but on the other, even a single faulty part can have more far-reaching effects than ever before. Faced with costly recalls, automotive manufacturers are confronted with increasingly complex requirements and stricter specifications. Is the effort of traceability worth it if it means labeling up to 20,000 parts per vehicle? Yes, it is, but powerful reading and verification technologies along with powerful software is needed to make sense of all the data.There are several reasons why manufacturers need to keep accurate records of the parts and components that make up a new car. From a quality perspective, for example, barcode tracking helps to ensure that the right parts are put together. Even more important, however, is the ability to trace each car part back to its original supplier. In the event of a recall or the discovery of a faulty part, manufacturers have to be able to quickly and comprehensively find out where each part came from. This is complemented by information such as batch number, date of manufacture and other important information to identify which vehicles are affected by a defective part. Recommendations and standards from AIAG, VDA, ANSI and ISO specify the details. As the automotive industry globalizes, worldwide production of light vehicles is expected to reach around 96 million units by 2023. This means that even a single faulty part can have an enormous impact, and therefore must be prevented at all costs.

Lights out? Still unlikely with Industry 4.0

21. april 2022 For many manufacturers, the prospect of a fully automated, human-free factory feels light years away. When, they ask, is the 4th Industrial revolution coming to us and what can we expect? In this blog, we look at the realities of (fully-/semi-)automated manufacturing, what robots can and can’t do, and why the human touch is still (mostly) irreplaceable.

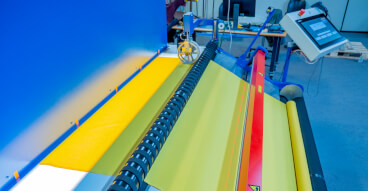

Vadain automates the inspection of curtain fabrics with machine vision

8. april 2022 Vadain, the market leader in custom curtains in the Netherlands, needed a solution to detect errors as early as possible in kilometers of curtain fabrics. Together with software developers from Sycade, OMRON machine vision technology, and machine builder Eisenkolb, they developed an automated solution to detect and analyze errors in curtain fabrics, making the time-consuming manual inspection process a thing of the past.

Traditional factories have data needs too

18. marts 2022 The right tools and tech can enable advanced predictive maintenance, bottleneck prevention and optimization. Find out how digitalization is bridging the gap between legacy systems and Industry 4.0.

Fuel for the future: What to look out for in fuel cell production

10. marts 2022 When people talk about sustainable mobility, the first thing that comes to mind is battery-powered e-cars. Fuel cells or direct hydrogen burners are complementary technologies that often fade into the background, yet have a lot to offer when it comes to CO₂ reduction and market options.

Mastering packaging and intralogistics challenges in eCommerce

24. februar 2022 Robot-assisted packaging enables fast and cost-efficient scalability upward and downward to handle swings in demands from the supply chain.

Innovative cobot application improves safety at Leica Geosystems

11. februar 2021 Collaborative robot automates tray handling and improves safety and ergonomics in a hazardous working area.

Developing smart and flexible production: Norwegian university sets up new manufacturing lab packed with robots

10. februar 2021 The Norwegian University of Science and Technology (NTNU) has developed a new educational laboratory in Ålesund to facilitate learning and extend the implementation of automation and robotics amongst manufacturers in the region. The lab is packed with a wide range of OMRON solutions – both hardware and software.

Powering the European automotive industry

29. januar 2021 The European automotive industry is facing strong competition from Asia, as well as the economic challenges of the pandemic. It needs to develop innovative, future-proof strategies and technologies that will boost both efficiency and sustainability. Tony Seba from Stanford University believes that by 2025, no more new vehicles with (pure) combustion engines will be sold and there will be a move towards battery or hydrogen-powered fuel cells. Meanwhile, the industry faces falling sales, increasingly strict emissions regulations, new technologies, digitisation and changing consumer needs. Companies must respond by converting their production lines; becoming more agile; and introducing innovations that provide a competitive edge.

ControlTec helps Polish hospital tackle the pandemic with a UVC mobile robot

26. januar 2021 Using an OMRON LD mobile robot, ControlTec was one of the first companies in the world to develop a sterilisation robot equipped with a UVC irradiator.

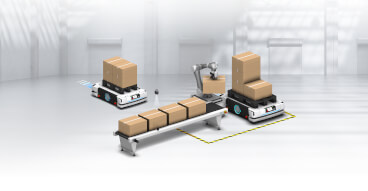

Fast and safe transport on the factory floor

18. januar 2021 Improved efficiency and seamless material supply: in Austria, Philips is automating material transport by using AMRs from OMRON.

Improved flexibility, agility and traceability with mobile robots for Normagrup

6. januar 2021 Normagrup, which specialises in technologically advanced lighting, needed to automate the transport of materials between three production areas, the assembly area and an automated warehouse. This involved moving through narrow spaces shared with factory personnel.

Mobile robot streamlines food deliveries

30. november 2020 A whistling autonomous mobile robot has been seen recently moving around the corridors of shopping centre in Helsinki, Finland. Operated by OMRON’s solution partner Dimalog, the robot was taking part in a month-long ‘Home On-Demand’ automated courier service trial.

3 Ways COVID-19 is Impacting Logistics Operations in the UK (and what to do about it)

4. november 2020 By Stuart Coulton, Regional Manager, OMRON UK North

What to consider when selecting a mobile robot for heavy loads

11. september 2020 Five questions to ask when selecting autonomous material transport technology for industrial applications.

Factory automation: four tips for the future of food & beverage manufacturing

16. juli 2020 The coronavirus pandemic has posed major challenges to organisations of all types and sizes. In the food and commodity industry, companies have faced significantly reduced consumption and disrupted supply chains, while at-home consumption increased, and out-of-home consumption came near to a standstill. But how can manufacturers adapt their business strategies and production processes both now and in the longer term? The pandemic may provide an opportunity for rethinking outdated processes and procedures and enhancing them with concepts such as innovative robotics, sensor technology and holistic automation strategies.

Cobots give gear manufacturer a competitive production edge

14. maj 2020 Danish gear manufacturer, Fischer Gears, has boosted the competitiveness of its production process - especially on larger series – by installing two OMRON TM robots. The collaborative robots (cobots) free experienced employees to focus on more value-adding tasks.

Made-to-order production with an advanced fleet of mobile robots

11. maj 2020 VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine mobile robots from Omron.